MRF MetalCoat is a multipurpose 100% aliphatic polyurethane finish for protection and durability. MetalCoat is available in a wide range of shades for application on metal surfaces and is ideal for grills, metal furniture, machinery components/body, bus bodies, steel structures, chemical plants and brass/bronze wares. Metal Coat is not only suitable for metal, but also for wood, plywood, MDF and plastics. Metal Coat is supplied as a 2 component PU system with base and hardner in the ratio 4:1. Application of Metal Coat is to be done after proper surface preparation with suitable primers and putties. Recommended system of application is by spray.

This coating is available in Clear, Glossy, Metallic and Matt finishes.

Features

- Aesthetic finish with exceptional gloss.

- Excellent gloss and colour retention.

- Exposure to heat and light does not yellow the film.

- Excellent UV resistance.

- Outstanding outdoor durability.

- Excellent corrosion resistance.

- Good resistance to chemicals and stains.

- Excellent flow and levelling characteristics.

- Superior Abrasion resistance.

Where to use

- Grills and gates

- Metal and wood furniture

- Bus bodies

- Steel structures

- Machines & Machinery components

- Chemical plants

- Aluminium components

- Brassware

- Plastic components

Specifications

- Base : Hardner - 4 : 1 by volume

- Pot Life 45 minutes

- Recommended Thinner - MRF Thinner for Finish

- Thinner intake - 20% by volume

- Coverage Area - 80Sqft / ltr / Coat

Application Procedure

For Metal

- De-grease the surface, make the surface oil and dust free.

- Sand the metal surface to remove any rust formation. For heavily rusted surfaces, use cloth emery grits 80-120. For lighty rusted surfaces, use grit 120-220.

- After cleaning, prime the surface using MRF Zinc Phosphate Epoxy Primer Grey/White by brush, roll or spray. Allow to dry for 6-8 hours.

- For galvanised steel and aluminium, use Metal Coat Etch primer in 2 thin coats, to etch the metal surface and make it receptive to primer. Allow to dry for 6-8 hours. Then prime the surface using MRF Zinc Phosphate Epoxy Primer Grey/White.

- Look for dents, cracks, holes, open welded joints, scratches etc. and fill them using MRF Metal Coat Polyester Putty. For large hole or dents, fill with Polyester Putty using successive thin coats. Allow to cure for approximately 30 minutes between putty coats. Sand the putty as necessary.

- Apply a second coat of MRF Zinc Phosphate Epoxy Primer Grey/White. Allow to dry for 6-8 hours.

- Depending on the need, a coat of Metal Coat Primer Surfacer can be applied to further smoothen the surface. Allow for cure time of 6-8 hours

- Mix the supplied MRF Metal Coat base:hardner in the ratio 4:1 by volume. For every 1 liter of mixed material, thinning by 200ml of MRF Thinner for Finish is recommended. Apply the first coat of MRF Metal Coat by spray, keeping the compressor pressure at 40-45 PSI. A HVLP gun is recommended for best results.

- Allow cure time of 6-8 hours between coats. Once cured, lightly sand the surface using water emery grit 800. Sanding with water is recommended to get even results.

- Apply a second coat of MRF Metal Coat using the same procedure as before.

- To gain a higher gloss, a single coat application of MRF Metal Coat Glossy Clear is recommended over the applied paint.

For Wood

- Sand the wood using emery grits 80-120 Aloxite paper for hard woods. For soft woods, use grit 120-220 Aloxite paper.

- After cleaning, prime the surface using MRF Metal Coat GPPS White/MRF Metal Coat PS Grey by spray. Allow to dry for 6-8 hours.

- Look for dents, cracks, holes, scratches etc. and fill them using MRF Metal Coat Polyester Putty. For large hole or dents, fill with Polyester Putty using successive thin coats. Allow to cure for approximately 30 minutes between putty coats. Sand the putty as necessary.

- Apply a second coat of MRF Metal Coat GPPS White/MRF Metal Coat PS Grey. Allow to dry for 6-8 hours.

- Mix the supplied MRF Metal Coat base:hardner in the ratio 4:1 by volume. For every 1 liter of mixed material, thinning by 200ml of MRF Thinner for Finish is recommended. Apply the first coat of MRF Metal Coat by spray, keeping the compressor pressure at 40-45 PSI. A HVLP gun is recommended for best results.

- Allow cure time of 6-8 hours between coats. Once cured, lightly sand the surface using water emery grit 800. Sanding with water is recommended to get even results.

- Apply a second coat of MRF Metal Coat using the same procedure as before.

- To gain a higher gloss, a single coat application of MRF Metal Coat Glossy Clear is recommended over the applied paint.

For Plastic

- Sand the plastic using emery grits 320-800 Water Emery paper.

- After cleaning, prime the surface using MRF Air Drying PP Primer by spray. Allow to dry for 6-8 hours.

- Look for dents, cracks, holes, scratches etc. and fill them using MRF Metal Coat Polyester Putty. For large hole or dents, fill with Polyester Putty using successive thin coats. Allow to cure for approximately 30 minutes between putty coats. Sand the putty as necessary.

- Apply a coat of MRF Metal Coat GPPS White/MRF Metal Coat PS Grey. Allow to dry for 6-8 hours.

- Mix the supplied MRF Metal Coat base:hardner in the ratio 4:1 by volume. For every 1 liter of mixed material, thinning by 200ml of MRF Thinner for Finish is recommended. Apply the first coat of MRF Metal Coat by spray, keeping the compressor pressure at 40-45 PSI. A HVLP gun is recommended for best results.

- Allow cure time of 6-8 hours between coats. Once cured, lightly sand the surface using water emery grit 800. Sanding with water is recommended to get even results.

- Apply a second coat of MRF Metal Coat using the same procedure as before.

- To gain a higher gloss, a single coat application of MRF Metal Coat Glossy Clear is recommended over the applied paint.

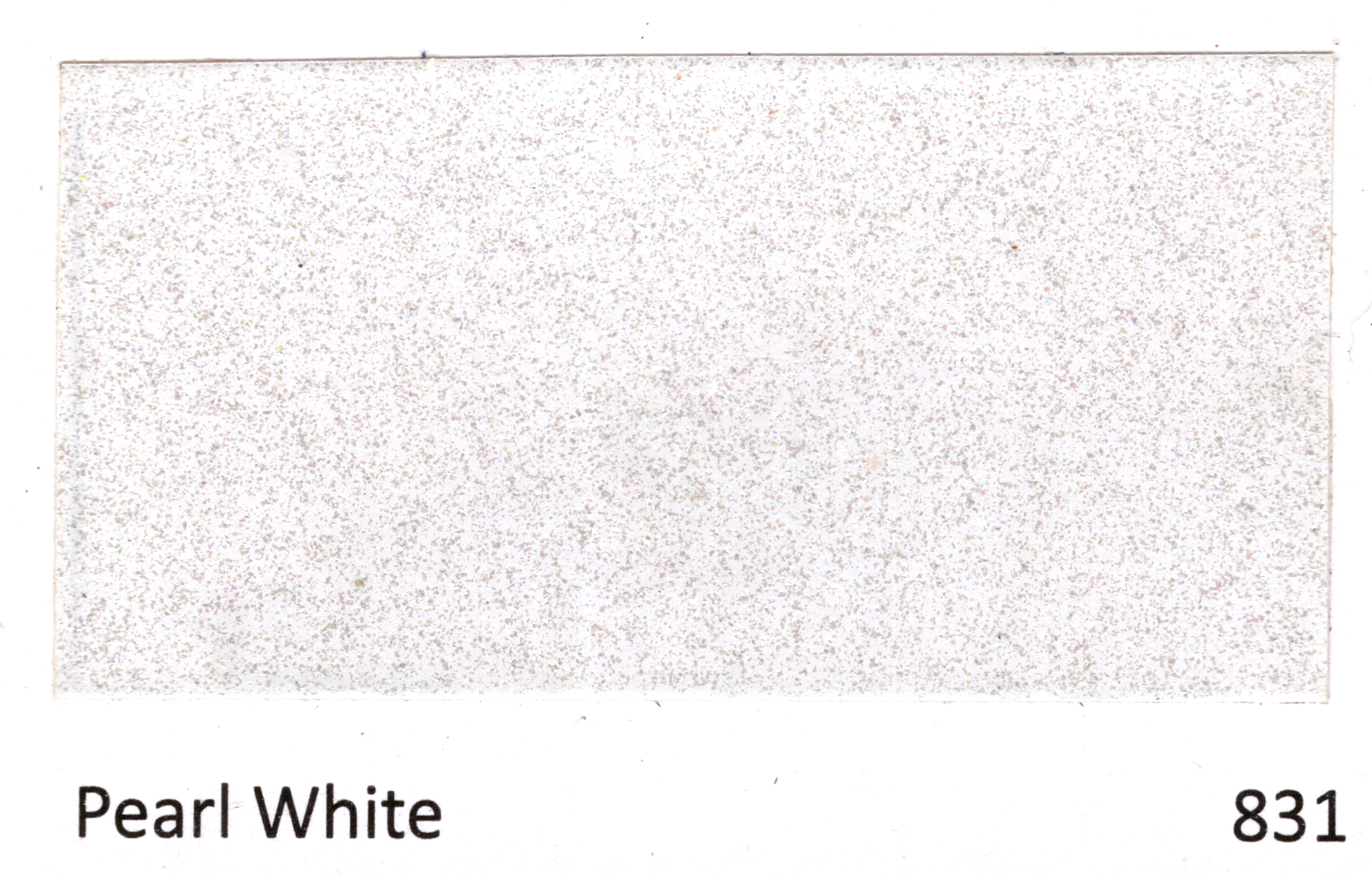

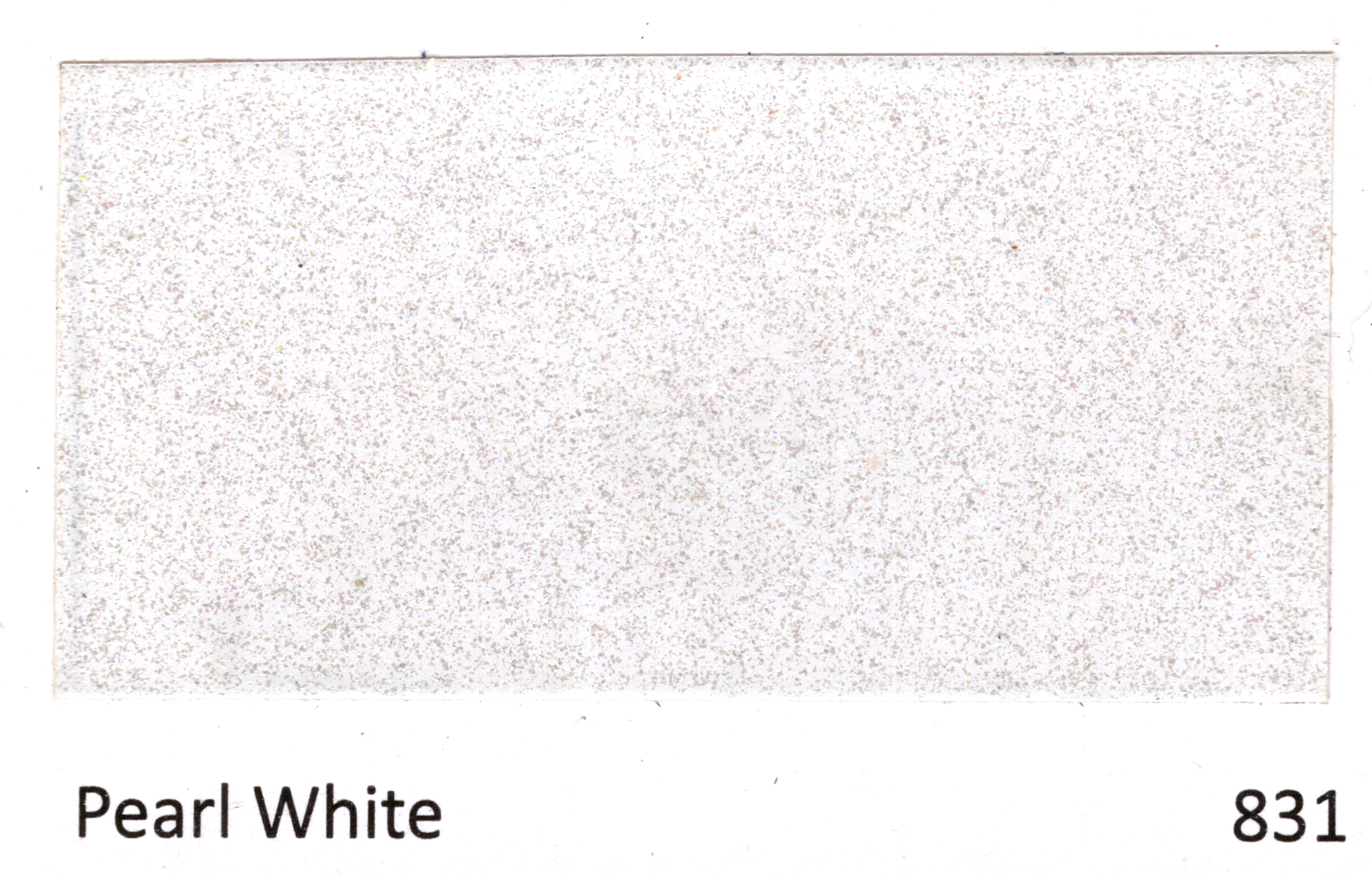

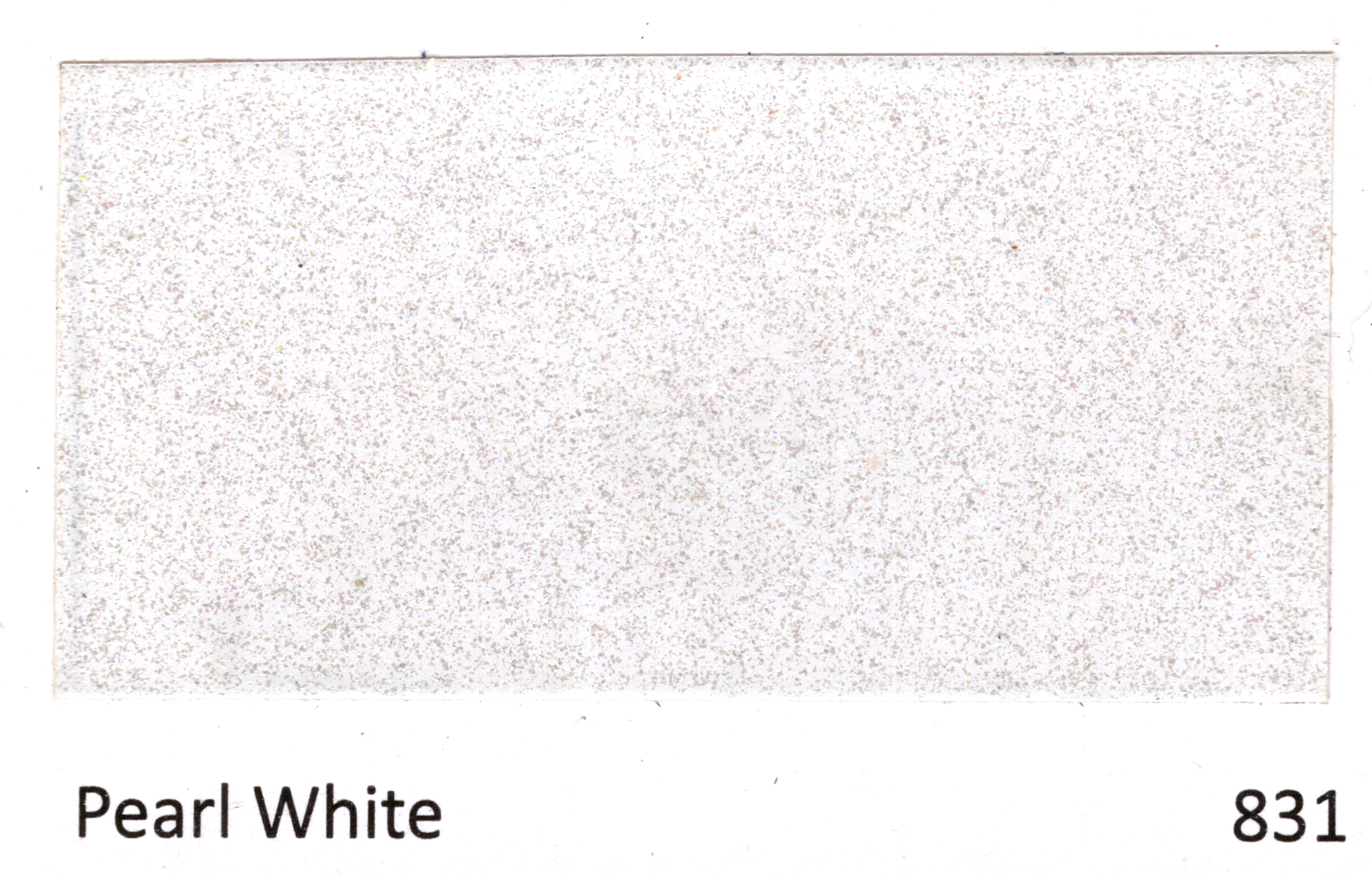

Especially for Pearl White

- Application of MRF Metal Coat Glossy Metallic Pearl White requires an under coat of Metal Coat Matt White for the desired effect to be achieved.

- After the application of primer, 2 coats of Metal Coat Matt White is required.

- This procedure is required as Pearl White by itself is translucent and requires a matt base for proper adhesion.

Recommended Products for use with Metal Coat

Under Coats

|

|

|

|

|

|

|

| Epoxy Primer Grey |

Epoxy Primer White |

Universal Primer |

Etch Primer |

PS Grey |

GPPS White |

Air Drying PP Primer |

Putties

|

| Polyester Putty |

Thinners

|

| Thinner for Finish |

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy