- New

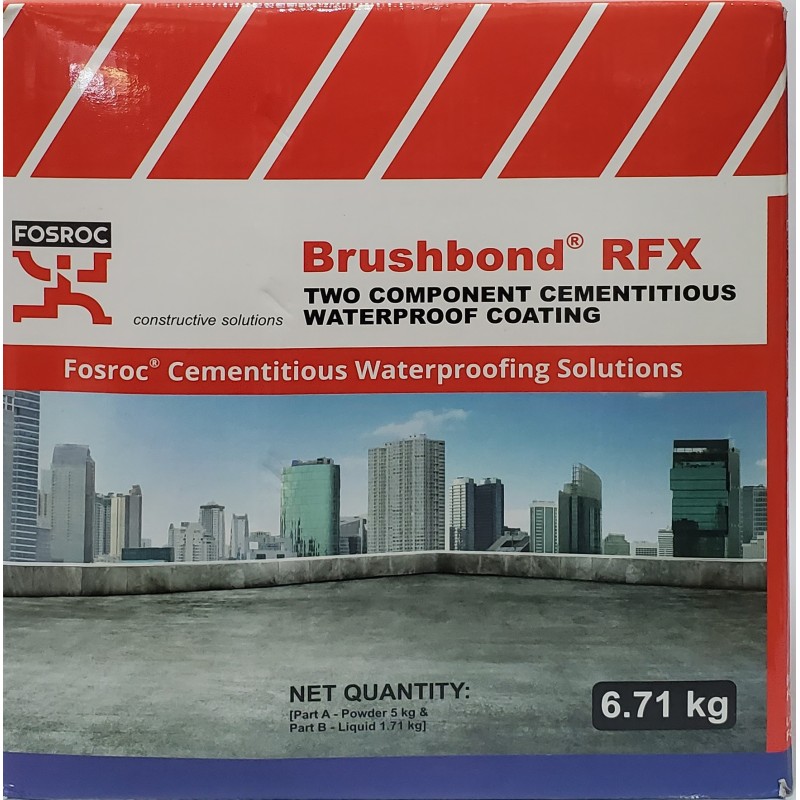

2 Component, High Performance, Acrylic Polymer modified Cementitious Waterproof & Anti-Carbonation Coating for Concrete Structures.

Security policy

Security policy

Read our Security Policy

Delivery policy

Delivery policy

Fast Deliveries

Return policy

Return policy

Easy Returns

Fosroc Brushbond RFX is a high performance 2 component Acrylic Polymer modified cementitious coating which consists of Brushbond RFX Powder and Brushbond RFX liquid acrylic emulsion. It requires only the addition of clean water at site to produce an easily brushable coating.

Brushbond RFX is a high performance elastomeric cementitious coating used for waterproofing and to protect atmospherically exposed reinforced concrete structures from attack by acid gases, chloride ions, oxygen & water.

The product can be used on concrete, brick and blockwork substrates and is equally suitable for new and existing structures. The product is designed to reface and even out variations in concrete and masonry surfaces and bridge shrinkage cracks. It provides a seamless, flexible waterproof coating suitable for water tanks, reservoirs, drainage culverts basements, roofs, toilets & wet areas. The product provides a tough durable water-resistant coating which can withstand light pedestrian traffic and also has excellent weather resistance for exterior applications.

Areas of Application

Features

Mixing Ratios

| Brusbond RFX powder | Brushbond RFX liquid | Water |

| 5Kg | 1.71Kg | 1Lt |

All surfaces which are to receive the coating must be free from oil, laitance, grease, wax, dirt or any other form of foreign matter which might affect adhesion. Typically, concrete surfaces can be cleaned using high pressure water jet or grit blasting or by proper wire brushing Spalled surfaces or those containing large blow holes, cracks and other such defects should be repaired using Renderoc concrete repair mortars. For further advice on suitable repair mortars, contact the local Fosroc Office.

Brushbond RFX liquid concentrate should be poured into a plastic container or metal drum. Clean fresh water is added in the proportions shown above and mixing commenced with a propeller agitator attached to a slow speed drill (500pm). The powder component should be added gradually to the liquid to avoid lump formation and mixed for 2-4 minutes. Brushbond RFX should be immediately used after mixing. Do not mix more material than can be used within the pot life. Keep stirring Brushbond RFX during the application.

For best results, surfaces should be damp. In order to obtain the protective properties of Brushbond RFX, it is important that the correct rates of application are observed. Use a short stiff brush preferably 120-150mm width and apply the mixed material like paint. The application of Brushbond RFX should not be done if the temperature of the substrate is below 0C. When applying Brushbond RFX on hot substrates i.e., over 300C surface temperature, saturate the surface with water. Apply Brushbond RFX in 2 coats to achieve 1mm wet film thickness. The second coat of Brushbond RFX shall be applied as soon as the first coat has reached touch dry state. It is recommended that for general surfacing Brushbond RFX should be applied at a minimum wet film thickness of 1mm. Areas subjected to moderate and heavy loads/hydrostatic pressure, minimum 2mm wet film thickness coating is recommended with screed above. Water curing OR Curing membrane shall not be applied over Brushbond RFX coating, only air curing is recommended.

Sprinkle sieved coarse sand on wet surface of final coating for better adhesion of plaster or screed. Allow the coating to dry for a minimum period of 7 days before covering with plaster on the vertical surface & 3 days before covering with screed plaster on the horizontal surface. Maximum thickness of cement plaster recommended is 12 to18mm & height of 1mt in a single day to avoid de-bonding of plaster from Brushbond RFX coating.

Any deviation from the above recommendation please contact Local Fosroc office for advice.

This depends on the required consistency. The approximate coverage per pack at even consistency (1mm wet film thickness) is as follows:

Consistency Brush application

Coverage (5kg+1.71kg pack) 4 - 4.5 sqm (40 to 45 sqft)

You might also like